Lab glassblowing is a highly specialized craft that combines precision engineering with artistic skill.

It begins with selecting the appropriate diameter of borosilicate glass tubing. The process starts as the glass tube is heated in a mixture of gas and oxygen until it becomes molten and workable glowing with an intense orange or red hue.

Glassblower then expertly pull, join, and shape the glass according to precise specifications. During the joining phase, the glassblower often connects the tube to a hose, blowing air into it to create a controlled bubble—forming the joint for laboratory apparatus.

With meticulous control, they turn, blow, and refine the shape, sometimes using molds for standardized parts or tools to achieve precise curves and connections.

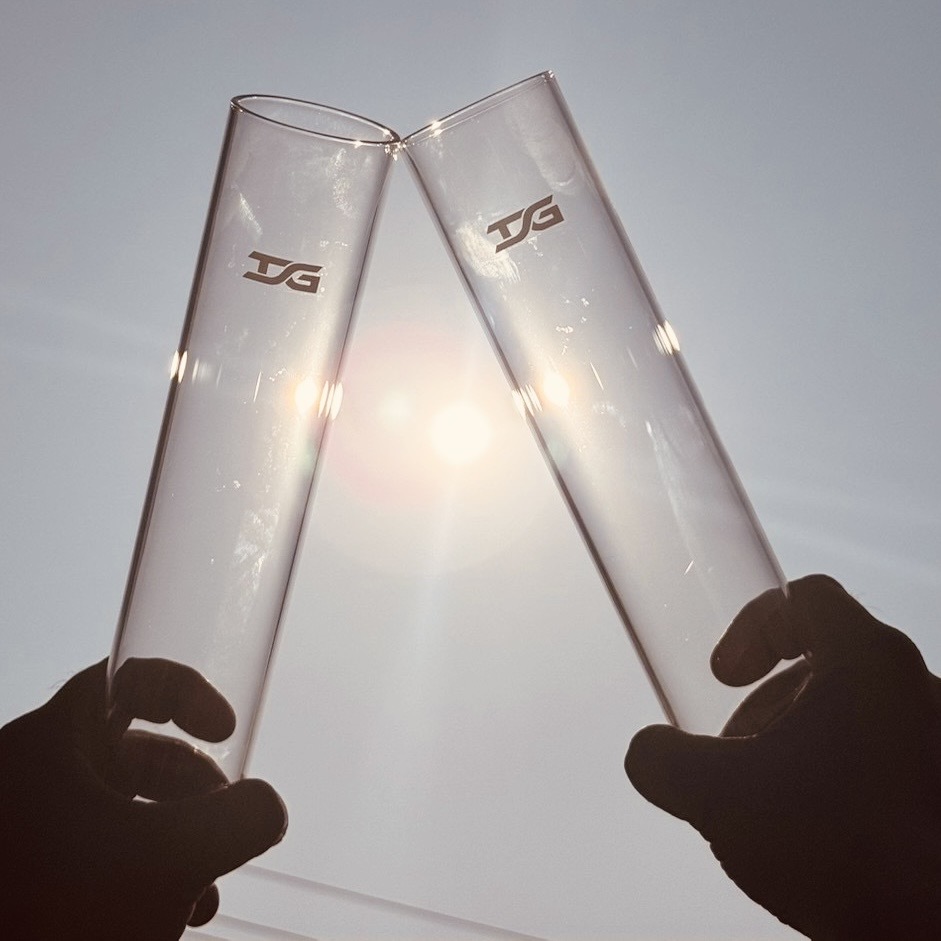

Throughout the process, cutting, grinding, polishing, and engraving to achieve the highest levels of accuracy and clarity—critical for scientific and experimental reliability.

At last, the glass is reheated and cooling in a furnace to relieve internal stresses, ensuring durability and safety.